COVID-19 has prompted companies to rethink their global supply chains, including the reshoring of manufacturing back from China.

The U.S. manufacturing industry is at a unique and unprecedented crossroads to reevaluate operations due to COVID-19, including costs, supply chain reliability and risk of significant near-term business interruption. Historically, manufacturing footprint decisions were driven by cost, including labor and logistics, which have continued to rise in developing countries in recent years. Footprint location decision criteria need to be expanded beyond the historic focus on production costs to include broader supply chain factors and post-COVID-19 risk mitigation considerations. Today, additional strategic criteria are being weighed as heavily as cost, such as critical manufacturing designation, product quality, intellectual property protection and environmental impact.

Kroll Reshoring Index

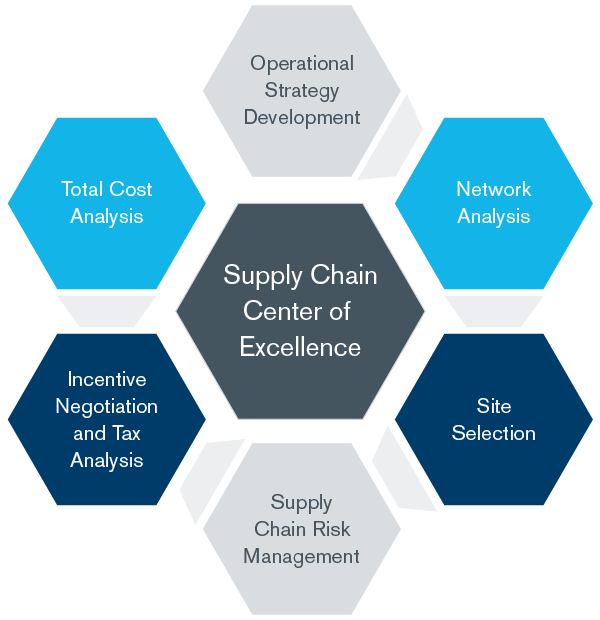

Kroll has developed an index with six cost, risk and strategic criteria to evaluate 28 U.S. manufacturing industry sectors, identified by North American Industry Classification (NAICS) codes, to score and rank the sectors most likely to reshore.

Our analysis suggests many products historically made in China and destined for U.S. consumers or other markets worldwide show high potential for being reshored. Additionally, navigational and control instruments, transportation equipment, medical equipment and communications systems have emerged as the most likely to lead reshoring to the U.S.

Hover over each industry sector to learn more.